- Home

- Model

- 001 (9)

- 5sme39hl0252 (9)

- 9100-1t3-01100g (11)

- At1-2200s (26)

- At1-2200x (12)

- At3-1500x (15)

- At3-2200x (39)

- At4-0750x (32)

- At4-1500x (57)

- Avss3 (11)

- Grinder Polishing (12)

- Horizontal (20)

- Intelliflo Vf 011012 (15)

- Lumberjack Rt1500 (11)

- M425-402 (23)

- M5120-402 5gn-180k (25)

- Nptq165 (10)

- Rt1500 (10)

- Vertical (74)

- Vm0103 (9)

- ... (4765)

- Set

- Shaft Diameter

- Speed

- Speed Ratio

- 1:100 - 0-14 Rpm (2)

- 1:12.5 0-112rpm (6)

- 1:120 (0-11.6rpm) (4)

- 1:120 - 0-12 Rpm (4)

- 1:150 0-9.3rpm (2)

- 1:180 0-7.8rpm (3)

- 1:25 (0-56rpm) (2)

- 1:3 (0-466rpm) (2)

- 1:3 - 0-466 Rpm (2)

- 1:300 0-4 Rpm (2)

- 1:300 0-4.7rpm (2)

- 1:36 0-38.8rpm (2)

- 1:40 (0-35rpm) (2)

- 1:50 0-28rpm (5)

- 1:540 0-2 Rpm (2)

- 1:60 0-21 Rpm (2)

- 1:600 0-2 Rpm (2)

- 1:600 0-2.3rpm (2)

- 1:750 0-1.86rpm (2)

- ... (5145)

- Voltage

Knife Making Vertical/Horizontal-Variable Speed 2 x 72 Belt Sander 2hp Motor

Knife Making : Industrial Duty, 2HP TEFC (Totally Enclosed Fan Cooled), Vertical-Horizontal, Variable Speed, 2" x 72" Belt Sander System. Please see the new upgrade: 2-1/4" wide x 5" diameter, Drive Wheel, taper mount directly on the motor shaft. The Variable Speed Controller seen in the listings may not be the actual unit that you will receive, because some are made for 220-240V Input. Lengths and width between 1" and 2". This unique system is custom designed and build specifically for knife makers.

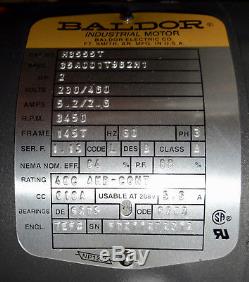

It is build to use popular 2" x 72"grinding belts. By Baldor 2HP 3450 RPM, 3 phase, continuous duty MOTOR.

It operates on standard 20-25 amp circuit from 110 Volt AC outlets (for most USA buyers) or 220-240VAC (for overseas customers). The listing photos show the. Its basic design and components.

This compact Sander sits on 12" x 14" x 1/4 thick solid steel base. Motor's native resolution is 3450 RPM.

Standard Features and what you are going to get. Sits on 12" x 14" x 1/4 thick solid steel base. The tracking arm with tension spring and 3 solid aluminum idle wheel. Tooling arm with 5th Generation Platen Attachment and Removable Platen Plate for a slack belt grinding.

Taper mount 5 diameter Drive Wheel (Convex for better tracking), mounted directly on the motor shaft. Tilt-adjustable and removable Work Rest Table. Size 10 x 6 and cut of 3/8 steel.Underneath is smaller 3" x 5" work rest table that can be used when the larger is not practical. Size 13 x 6 made specifically for Horizontal grinding. Its own smaller Tooling Arm is also detachable. This Sander Stand may be removed if you don't need horizontal type often. Makes the whole machine lighter.

The Motor (2hp) is powered directly from the household wall outlet through the VFD Kit. All the wheels are made of aluminum. More detailed info regarding wheels is available from my other listings.

(combine machine weight could be in excess of 150 lb). Listing photos must serve with the basic assembly because there is no manual or additional instructions. All necessary adjustments except for belt tracking are done during testing. When assembled it should be ready for work right out of the box (so to say).Approximate arm-tightening position for the proper belt tracking is marked on the Platen Tooling Arm. It may change slightly when different brands and belt thickness are used. It is a full-featured, industrial quality, space saving, small footprint and compact unit. Each unit is build and assembled individually. It is not a result of mass production.

Based on the same design, it may however differ slightly in dimensions, color or finish. No unit will be sent without going through testing. It will be put together, mounted on table, powered and run.At this stage adjustment will be done, to make sure that every part is working fine. Later on you may find it useful to make certain improvements, like perhaps spark trap, eye and V-belt shields, etc.

If you own a compressor I would also recommend blowing the dust off regularly in order to keep the work space nice and clean. Additions are possible like perhaps Rubber Contact Wheel or the Small Wheel Attachment. Because each machine is individually build and assembled, there may be small design differences between the listing photos and the actual machine you will receive.This however has no effect on performance and usually improves the overall good look. The item "Knife Making Vertical/Horizontal-Variable Speed 2 x 72 Belt Sander 2hp Motor" is in sale since Saturday, December 1, 2018. This item is in the category "Home & Garden\Tools & Workshop Equipment\Power Tools\Sanders". The seller is "starcrust2000" and is located in Anderson, South Carolina. This item can be shipped to United States, United Kingdom, Denmark, Romania, Slovakia, Bulgaria, Czech republic, Finland, Hungary, Latvia, Lithuania, Malta, Estonia, Australia, Greece, Portugal, Cyprus, Slovenia, Japan, China, Sweden, South Korea, Indonesia, Thailand, Belgium, France, Hong Kong, Ireland, Netherlands, Poland, Spain, Italy, Germany, Austria, Bahamas, Israel, Mexico, New Zealand, Singapore, Switzerland, Norway, Saudi arabia, Ukraine, United arab emirates, Qatar, Kuwait, Bahrain, Croatia, Malaysia, Brazil, Colombia, Panama, Jamaica, Barbados, Bangladesh, Bermuda, Brunei darussalam, Bolivia, Ecuador, Egypt, French guiana, Guernsey, Gibraltar, Guadeloupe, Iceland, Jersey, Jordan, Cambodia, Cayman islands, Liechtenstein, Sri lanka, Luxembourg, Monaco, Macao, Martinique, Maldives, Nicaragua, Oman, Pakistan, Paraguay, Reunion, Viet nam.

- Country/Region of Manufacture: United States

- MPN: Does Not Apply

- Brand: Unbranded